T-TZ

Ponudba brizgalnih čistilnih naprav Alfa Laval T/TZ za rezervoarje zagotavlja izjemno čistost, boljšo kakovost končnih izdelkov, večjo skupno zmogljivost in nižje obratovalne stroške. Te naprave so zasnovane za higienske postopke v živilski in mlečni industriji ter industriji pijač. Na voljo je v različnih velikostih in konfiguracijah, ki pokrivajo vse velikosti rezervoarjev.

Temeljito stroškovno učinkovito čiščenje

Rotacijske brizgalne glave Toftejorg za doseganje najboljših rezultatov čiščenja uporabljajo optimiziran močan vzorec curka, ki zagotavlja maksimalno pokritost površine. Vzorci čiščenja segajo do notranjih površin rezervoarja, kar zagotavlja najučinkovitejšo možno rešitev čiščenja brez razstavljanja (CIP). Tlak curka in sila ob stiku s površino učinkovito odstranjujeta ostanke in zagotavljata ustrezne higienske pogoje, ki so potrebni za proizvodnjo serij. Vse rotacijske brizgalne glave Toftejorg tako od zunaj kot od znotraj omogočajo samočiščenje in samopraznjenje ter so v skladu z veljavno dobro proizvodno prakso (cGMP). Sistem Alfa Laval Rotacheck preveri vsak cikel čiščenja, da zagotovi skladnost z današnjimi strogimi higienskimi standardi.

Do okolja prijazna in gospodarna rešitev

Rotacijske brizgalne glave Toftejorg brez razpok učinkovito čistijo rezervoarje z manj vode, energije in čistil kot statične brizgalne glave. S tem ne zmanjšate samo porabe čiste vode, električne energije in kemikalij, temveč tudi izboljšate okoljski profil svojega podjetja.

Zanesljivo delovanje in dolga življenjska doba

Tehnologija rotacijske brizgalne glave preverjeno povečuje učinkovitost čiščenja, saj zagotavlja zanesljive in ponovljive rezultate. Vrtljive brizgalne glave Toftejorg so zasnovane tako, da zagotavljajo minimalno izgubo notranjega tlaka in se vrtijo s tlakom, ki je manjši od 0,3 bara; kljub temu je za optimalno učinkovitost čiščenja priporočljiv delovni tlak med 5 in 8 bari.

Površine čisti s koncentriranimi curki in 360-stopinjsko pokritostjo. Največji učinek in najmanjša poraba tekočine v najkrajšem času.

Visoka celovitost izdelka

Da bi zagotovili celovitost izdelka, so vse rotacijske brizgalne glave Toftejorg izdelane iz varnih in nereaktivnih higienskih materialov. Vsi materiali iz nerjavnega jekla so v celoti sledljivi v skladu z ES št. 1935/2004. Vsi uporabljeni nekovinski deli so skladni z zahtevami FDA 21CFR § 174; nekovinski deli rotacijskih brizgalnih glav, ki se uporabljajo v biofarmacevtski industriji, so certificirani v skladu s predpisi USP razreda VI. Na zahtevo lahko za naprave za čiščenje rezervoarjev, ki ustrezajo standardu EN10204, zagotovimo certifikate 3.1. Certifikat ima tudi rotacijska brizgalna glava.

Uporaba v pomorstvu

T-82, ki se uporablja v obmorski industriji ter v petrokemični in kemični predelovalni industriji, je podmazan z mastjo in zasnovan za čiščenje rezervoarjev v zahtevnem okolju, tako se denimo pogosto uporablja v rezervoarjih za blato na oskrbovalnih plovilih in naftnih ploščadih, kjer so v čistilnem mediju trdi delci. Pogosto se uporablja tudi na barkah in tankerjih za prevoz proizvodov.

Stroja TZ-82 in TZ-75 se pogosto uporabljata kot prenosna stroja za čiščenje cistern na tankerjih za nafto, proizvode in kemikalije.

Prednosti izdelka

- 60 % hitrejše čiščenje = več časa za proizvodnjo

- Intenzivno čiščenje s 360-stopinjskim ponavljajočim se vzorcem čiščenja

- Nadzor postopka CIP s preverjanjem čiščenja

- Prihranite do 70 % stroškov čiščenja

- Higienska varnost z zanesljivim in predvidljivim čiščenjem

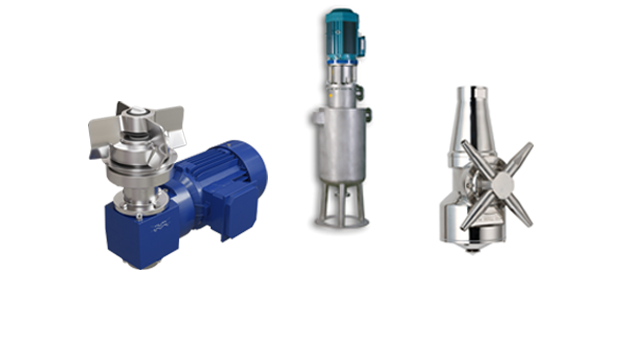

Ponudba izdelkov T/TZ:

- T-82

- TZ-66

- TZ-67

- TZ-75

- TZ-750

- TZ-82

- TZ-89

- TZ-68

Trajnost – Rotacheck

Alfa Laval Rotacheck ponuja preverjanja postopka čiščenja z rotacijskim curkom ter zmanjšuje porabo vode in izgubo izdelkov. Zagotavlja mirnejši spanec.

Kako deluje

Dinamični stroji za čiščenje rezervoarjev

Močan curek rotacijske brizgalne glave s štirimi šobami je vnaprej programiran za vedno gostejši nanos v notranjosti rezervoarja. Tako boste porabili manj vode, kisline ali jedkega sredstva in dosegli velik učinek. Hitrejši cikel čiščenja rezervoarja zmanjša tudi porabo energije.

Pretok čistilne tekočine omogoča vrtenje šobe okoli navpične in vodoravne osi. Šobe v prvem ciklu na površino rezervoarja na grobo razpršijo vzorec. Z nadaljnjimi cikli vzorec postaja vse gostejši, dokler po osmih ciklih ne dosežemo popolne pokritosti. Vse to poteka samodejno in uporabnikom zagotavlja učinkovito pot do zagotavljanja kakovosti pri čiščenju rezervoarjev in vso potrebno dokumentacijo.

Vrtljive brizgalne glave Toftejorg so idealne za čiščenje rezervoarjev za procesiranje, skladiščenje ali transport ter drugih posod, ki se uporabljajo v predelovalni, sanitarni, farmacevtski in drugih industrijah.

Del široke ponudbe opreme za rezervoarje

Alfa Laval ponuja celovito paleto opreme za čiščenje rezervoarjev za industrijsko uporabo, denimo za gnojila, anorganske kemikalije, petrokemikalije, biogoriva, nafto in plin, osebno nego, proizvodnjo papirjain celuloze ter proizvodnjo jekla.

Za širšo ponudbo opreme za rezervoarje si oglejte različne kategorije izdelkov: rotacijske brizgalne glave, rotacijske razpršilne glave, pribor za rezervoarje in pokrove rezervoarjev.

Deset najboljših nasvetov - Oprema za rezervoarje

Tukaj lahko najdete nekaj nasvetov in servisnih posnetkov, ki vam prikazujejo, kako ohraniti vrhunsko kondicijo opreme rezervoarjev.

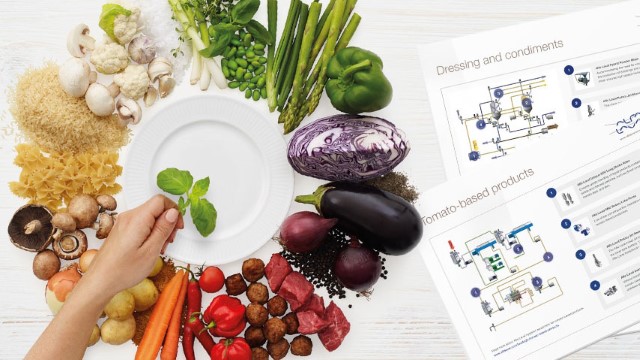

Logika za živila - Food logic

Higienska oprema Alfa Laval združuje visoko zmogljivost in nežno uporabo, da varuje občutljive sestavine. Sledi trendom živilske industrije in rešuje štiri ključne izzive: dobava živilskih izdelkov potrošnikom po konkurenčni ceni, doseganje kar najboljšega izkoristka surovin, zmanjšanje odpadkov in emisij ter dobava varnih in higienskih živilskih izdelkov.

Katalog izdelkov higienske opreme

Katalog izdelkov higienske opreme Alfa Laval »Na dosegu roke« vključuje letake izdelkov, krivulje učinkovitosti, povezave do animacij, brošure in cenike za naročanje.

Animacije

Obiščite stran z animacijami in poglejte naše proizvode od znotraj. Preverite kako delujejo.

NEAR novice

Da bi bili na tekočem o pomembnih zadevah in priložnostih v vaši industriji in procesih.