Neutralization systems

Increase the quality, stability and shelf life of edible oils with Alfa Laval neutralization systems. These high-performance acid systems remove free fatty acids and other impurities from crude oil, ensuring cleaner, more stable oil. Tailored to your needs, these systems boost yield, enhance taste, and streamline downstream operations. By supporting the complete refining process of edible oil, they reduce oil loss and operating costs while ensuring quality edible oil.

Improve edible oil refining with reliable neutralization systems

- Ensure more uptime and longer service life through robust system design

- Maximize edible oil quality, taste, shelf life and yield

- Boost operational reliability and efficiency

- Minimize oil loss and reduce operating costs

- Simplify installation, operation and maintenance

Achieve consistent performance in your edible oil refining with Alfa Laval neutralization systems, designed to optimize every stage of the process of neutralization. These acid neutralization systems effectively remove free fatty acids and associated impurities, reducing acidity and enhancing oxidative stability.

Engineered for high-efficiency refining, these neutralization systems reduce operating costs, maintain consistent product quality, and maximize yield. And with Alfa Laval’s global network of service centers and partners, you have easy access to reliable local support throughout the lifecycle of your system.

With Alfa Laval's neutralization systems, you can enjoy true peace of mind knowing that optimized processes are in place to boost the productivity and yield of your edible oil refining processes.

How the process of neutralization works

The process of neutralization is a critical step in edible oil refining. As free fatty acid levels increase, more intensive processing and higher caustic soda dosing are required to ensure effective removal of free fatty acids and other impurities. The crude oil is heated, mixed with acid, then dosed with caustic soda (lye), mixed again, then held in retention tanks, where the bonds between the oil and residual impurities are broken. Disc stack centrifuges then continuously neutralize the oils and fats.

Generally speaking, there are two methods to neutralize fats and oils:

Long-mix refining process for crude soybean or rapeseed oil

Used for crude soybean or rapeseed oil, this method neutralizes the free fatty acids by heating and dosing crude oil with acid and lye. The oil remains in contact with caustic soda for an extended period in special retention mixers. It is then heated and transferred to disc stack centrifuges, where soapstock and wash water are separated from the refined oil in a single stage.

Multi-mix refining process for virtually any oil

Suitable for refining virtually any oil, this method exposes the crude to the caustic soda for a short period. It then goes through one to two stages of washing. When processing cottonseed oil or low-quality crude fats and oils, a second lye treatment, known as re-refining, is required.

After neutralization, the oil is washed. Disc stack centrifuges then separate the wash water from the oil, which is transferred to a vacuum dryer for drying. The free fatty acids and other impurities (sugars, pigments, and trace metals) separated from the oil are sent downstream as soapstock, which can be processed in a soapstock splitting process to produce fatty acids.

Alfa Laval neutralization systems also support the refining of cottonseed oil and cold refining of sunflower or maize/corn oil.

Naše stranke

The Imcopa soybean oil refinery

The Imcopa soybean oil refinery in Brazil decided on an upgrade path to tackle very high steam costs, plus problems with poor heat recovery in the company’s existing plant.

Benefiting from the Alfa Laval retrofit concept, Imcopa upgraded an existing deodorizer and installed a new neutralization and bleaching line, plate heat exchangers, mixers and a PX 95 separator. This enabled the company to boost refinery capacity from 400 to 600 tonnes daily. This retrofit strategy, combined with Alfa Laval heat transfer technologies, enabled Imcopa to reduce overall production costs by more than USD 3 per tonne of oil – the investment paid for itself in less than 2 years.

The Bunge Group

The Bunge Group is a global agribusiness and food operation. The group’s Food Products division is Latin America’s largest oil seed processor and largest seller of bottled oils to the retail market. In addition, Bunge has invested in the largest vegetable oil refinery in Latin America to extend this position. Located in Brazil, this major plant has a capacity of 1200 tonnes per day.

Alfa Laval is responsible for the complete refinery, featuring a neutralization section with two PX 110 separators, a bleaching process installation and a complete SoftColumn deodorization solution.

Neutralization System Process

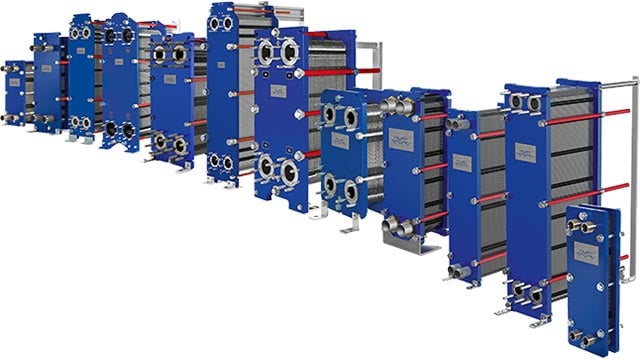

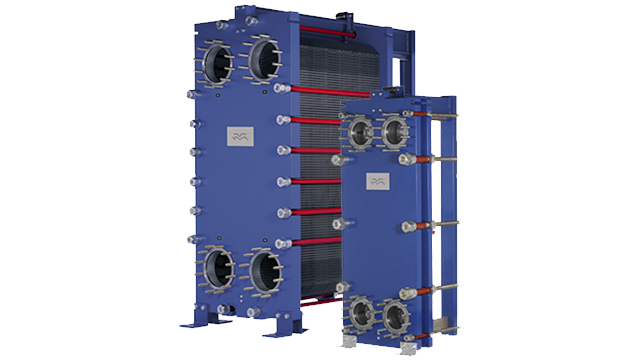

The Alfa Laval Neutralization System consists of heat exchanges, dosing pumps, mixers, agitators and disc stack centrifuges.

Key edible oil processing equipment used in our systems

Elevate the performance of your edible oil refining systems

Resource-smart production is essential as edible oils play a critical role in global food security. Optimize your processes over the entire lifecycle of your edible oil systems with the Alfa Laval service portfolio.

Leverage our full range our services - from system design, precision engineering, and effortless installation to commissioning, cost-effective operation, routine maintenance, and system upgrades.

With tailored service agreements, you can reduce waste, safeguard product quality, simplify operations, and maximize your return. Focus on the growth of your business while our global network and local providers take care of the rest.

Webinars for the Edible Oil industry

Our experts share know-how to optimize edible oil refining processes, remove impurities and volatile components for better product quality, safety and yield.