TJ40G-HD

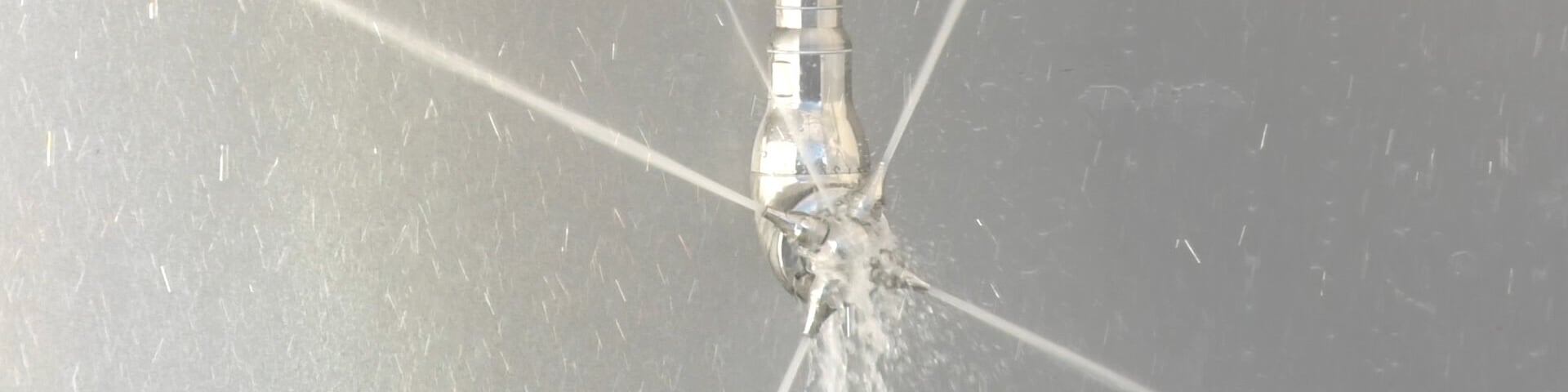

Rotary jet head tank cleaning for heavy-duty applications

High impact quality assured cleaning in a 360° repeatable cleaning pattern

- Avoid contamination with effective cleaning performance and superior self-cleaning features

- Cost efficient and sustainable solution reduces cleaning costs by up to 70% (water and chemicals)

- More available production time with up to 60% faster cleaning times

- Easy to service and maintain – no special tools required

- Control of CIP through validated cleaning

The Alfa Laval rotary jet head TJ40G-HD is for applications where larger amounts of particles in the cleaning liquid are re-circulated over the machine. Its special design ensures that particles do not get trapped inside the machine or damage / block the machine during operation.

Učinkovito čiščenje rezervoarjev z nizkimi obratovalnimi stroški

Močan curek ustvarja veliko mehansko silo in pokriva 360° ter tako učinkovito odstrani preostale izdelke in ostanke ter zagotovi najboljše higienske pogoje za proizvodnjo. Z večanjem sile, ki jo ustvarja rotacijska brizgalna glava, se zmanjšuje poraba vode, kar vodi do precejšnjih prihrankov pri stroških, kot je prikazano na diagramih. (na podlagi filozofije čiščenja dr. Sinnerja)

- Prihranek stroškov (voda, kemikalije): 70 %*

- Prihranek časa = več časa za proizvodnjo: 60 %*

* v primerjavi s klasičnim čiščenjem s statično razpršilno kroglico

Statična razpršilna kroglica

Alfa Laval TJ20G / TJ40G

Yellow = Temperature

Grey = Chemicals

Modro = poraba vode/časa

Rdeče = mehansko delovanje

Rumeno = temperatura

Sivo = kemikalije

Learn more

You can read more about the efficiency, practicality and technical details of the TJ40G Rotary Jet Head tank cleaning devices.

How it works

How does the TJ40G work? Click here to find out.

Validate your tank cleaning process

Alfa Laval Rotacheck validates the rotary jet heads cleaning process, reduces water consumption and product loss. Provides peace of mind.

Krajši čas čiščenja, večja proizvodnja pijač

Današnji trg pijač je veliko bolj zahteven kot nekoč. Kako se spopadate z izzivi hitre optimizacije čiščenja brez razstavljanja (CIP) na proizvodni liniji pijač?