Sistem zaprtega vodnega kroga hlajenja

To cool key processes in petrochemical plants, refineries, power plants and other heavy-duty industrial environments, many plant owners and operators rely on closed-loop cooling as the preferred cooling method. For cost-efficient and long-lasting closed-loop cooling, count on Alfa Laval’s broad range of plate heat exchangers and filters for safe, reliable, effective and environmentally sound operations.

On the pulse of closed-loop cooling systems

Alfa Laval is a world-class supplier of closed-loop cooling solutions for just about any industry where such solutions play a key role. Alfa Laval offers a cost-efficient range of large plate heat exchangers and self-cleaning filters. We also have the expertise to design optimized combinations of the two, and the project management experience to deliver according to specification.

Easy to clean, easy to adapt capacity

Plate heat exchangers are, in many ways, ideal for closed-loop cooling and utility duties. Compact, efficient and flexible, they can easily be adapted to accommodate changes in capacity. In addition, their fouling-resistant design minimizes cleaning requirements.

Compared to other technologies such as stand-alone cooling towers, closed-loop cooling with plate heat exchangers requires less make-up water and minimal water treatment. Consequently, there is less maintenance and less pumping – both of which significantly reduce operating costs.

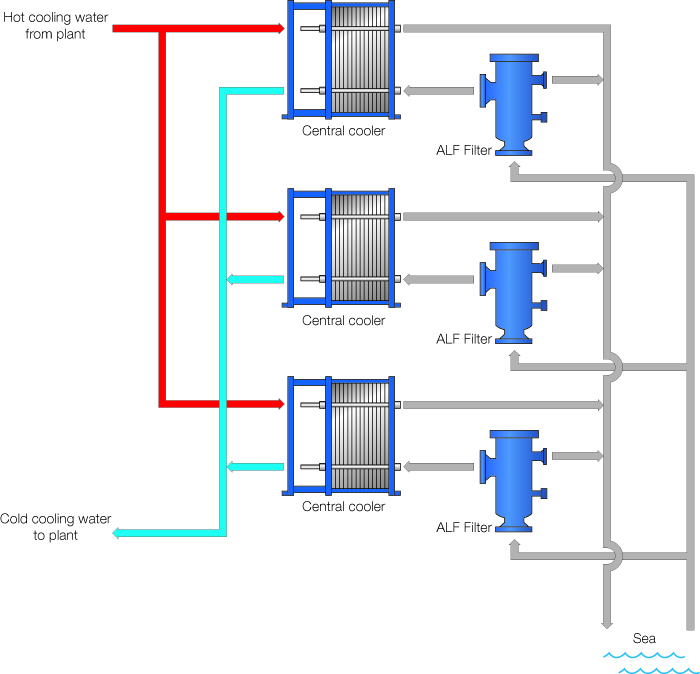

Combined filter and heat exchanger installation

ALF is Alfa Laval’s all-purpose filter designed for installation together with Alfa Laval plate heat exchangers in closed-loop cooling applications as well as for many other filtration duties. Alfa Laval ALF filters remove unwanted material – including sand and various biological matter – from the cooling water before it enters the plate heat exchangers. This minimizes plate heat exchanger maintenance and cleaning while maximizing equipment service life. Alfa Laval ALF filters are self-cleaning and require virtually no maintenance.

Closed loop cooling process overview

Prednosti

- Ščiti vodne vire pred onesnaženjem

- Na notranji strani zaprte vodne zanke ni obraščanja

- Idealna rešitev za naknadno opremljanje cevnih izmenjevalnikov

- Potrebuje le 20 % prostora v primerjavi s cevnim izmenjevalnikom

- Rešitev, ki je odporna proti koroziji