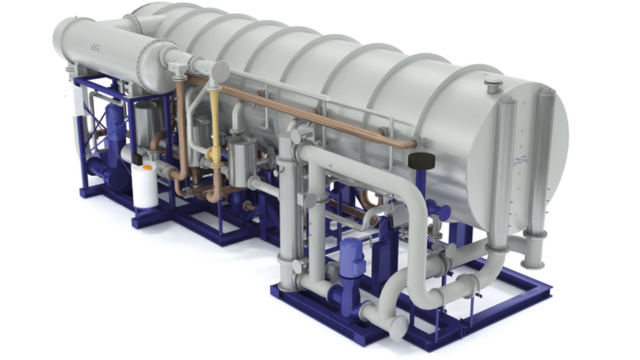

MEP - Multi efektivni ploščni uparjalnik

Fresh water is essential on board any ship, and needs to be available at any time. Whether that’s for human consumption, or for use in operational processes, it needs to be accessible anywhere in the world. With MEP evaporation, you continue to benefit from high purity fresh water even in harsher, variable external conditions.

The more efficient way to generate fresh water

- Low thermal heat and electrical power consumption

- Maintains efficiency and productivity in cold seawater or shallow water

- Can operate on the steam outlet of the steam turbine generator

- Produces high distillate purity of 5-10 ppm

- Water can be used for potable or technical use as required

The plate technology

Alfa Laval's distillation equipment consists of a number of titanium plate heat exchangers, which have been specifically designed for this purpose. All plates are identical; with two gasket configurations being utilised in order to form both a condensing and an evaporating plate channel. Compared to traditional shell and tube technology, the Plate Technology gives higher thermal efficiency. A continuous thin film of water over the entire plate surface also minimizes the risk of deposit build-up (scale) and thereby downtime. Corrosion-resistant titanium heat transfer surfaces and non-coated materials withstand seawater and brines.

Engineered efficiency

Straightforward operation and automated control provide maximum uptime at less cost compared to technologies such as reverse osmosis (RO) and multi-stage flash (MSF). Its lightweight, space-saving design takes up less floor space while offering much higher thermal efficiency in relation to its volume and weight compared to other evaporators. This enables the production of much higher volumes of fresh water than other desalination technologies.

Perfect fit for LNG ships

This technology works exceptionally well LNG fuelled ships, as they will typically have more excess heat available, and MEP works on waste heat recovery. As more ship owners look to make the shift to LNG due to emissions regulations, MEP is the ideal solution to further reduce costs. The fact that this system requires less power, and better facilitates the switch to LNG, also means it can make vessels significantly more environmentally friendly.

Kako deluje

Operating principle

The Alfa Laval MEP desalination process involves a series of evaporation and condensation chambers called effects, each equipped with patented Alfa Laval plates. Seawater is heated and partially evaporated in these chambers, producing distillate vapor, which is then condensed into pure distillate in the next chamber.

By maintaining a partial pressure difference across the effects, the system maximizes efficiency using low-grade thermal energy. The number of effects in a unit determines its performance and cost.

Seawater is pumped into the system, acting as a coolant in the condenser, where the vapor from the last effect is condensed into pure distillate. Heat from the condensed vapor is transferred to the seawater, which is then preheated and directed to the evaporation side of the plate stack. The special design of the plates ensures uniform flow and minimizes scaling. The seawater is partially evaporated by the heat from the condensation side, and the vapor produced is passed through a demister to remove salt before condensing into distilled water in the next chamber.

This process is repeated in all effects, with distillate and brine extracted from the last effect. The system operates under sub-atmospheric conditions, maintained by a water-driven ejector that removes air and non-condensable gases.

Contact our experts today to discover how the MEP Multi-Effect Plate Evaporator can optimize your operations.