FilmVap

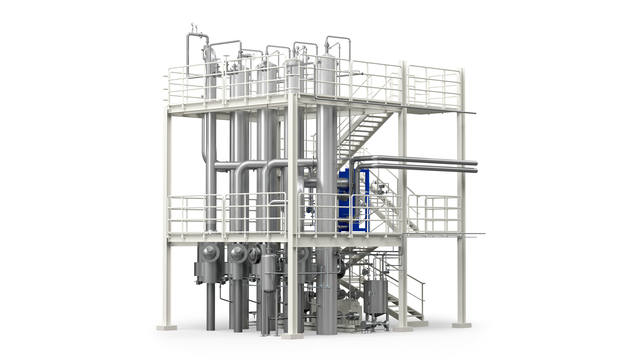

Boost productivity and cut energy costs with the Alfa Laval FilmVap falling film evaporator. Engineered for high efficiency and minimal fouling, it concentrates low- to medium-viscosity, heat-sensitive fluids. Get more uptime, higher capacity, and lower operating costs. The FilmVap’s compact, multiple-effect design outperforms traditional shell-and-tube systems in demanding industrial applications.

Optimize concentration with FilmVap falling film evaporators

- High quality condensate due to efficient liquid distribution and vapour-liquid separation under vacuum conditions

- Low maintenance requirements due to low temperatures and high heat transfer efficiency, which reduce fouling

- Robust, user-friendly design with broad operating range for more uptime and low maintenance

- Versatile, easy to operate and highly adaptable to a wide variety of applications and capacities up to 50 tonnes per hour in a single unit

- Enhanced energy efficiency using a multiple-effect arrangement or the addition of thermal vapour recompression or mechanical vapour recompression unit

Boost efficiency and increase product quality with the Alfa Laval FilmVap falling film evaporator. Ideal for temperature-sensitive, low- to medium-viscosity liquids, it delivers high heat transfer with minimal fouling – thanks to short residence time and low temperature differences. You get consistent performance, reduced energy use, and maximum uptime.

Compact and reliable, it is easy to operate and maintain, with capacities up to 50 tonnes per hour. Further reduce energy costs by adding multiple effects or integrating thermal vapour recompression (TVR) and mechanical vapour recompression (MVR) units.

Whether concentrating spent wash, fruit juice, or plant-based protein streams, FilmVap adapts to your needs, and helps you achieve higher yield at lower costs.

Pioneer management is very happy with the commitment level, technical competency and dedication of the Alfa Laval team. – Mr. S.S. Tomar, Chief Executive Officer, Pioneer Industries Ltd., Pathankot Punjab, India (Energy savings from concentrating spent wash from grain-based distillery using alcohol vapour from the distillation columns as the only heating medium/fuel.)

After finalizing on our requirement for the new bio methanated spent wash evaporator plant, we discussed our vision of achieving zero liquid discharge with Alfa Laval experts. Alfa Laval came up with the innovative feed degasification and condensate stripping systems. – Mr. H.K.Yadava, General Manager – Distillery, Harinagar Sugar Mills, Bihar, India (Zero liquid discharge from distillery wastewater.)

Platter distributor

Caption: The FilmVap platter distributor ensures uniform liquid flow and complete tube wetting in the vertical heating tubes – minimizing fouling and extending cleaning intervals.

Process liquid enters at the top of the evaporator through a precision-engineered platter distributor. The distributor ensures the uniform liquid flow into, and complete tube wetting of, the vertical heating tubes, minimizing fouling and extending the mean time between cleanings. Integrated vent tubes maintain pressure balance above and below the distributor plate, which keeps the load evenly distributed across all tubes and supports stable, efficient operation.

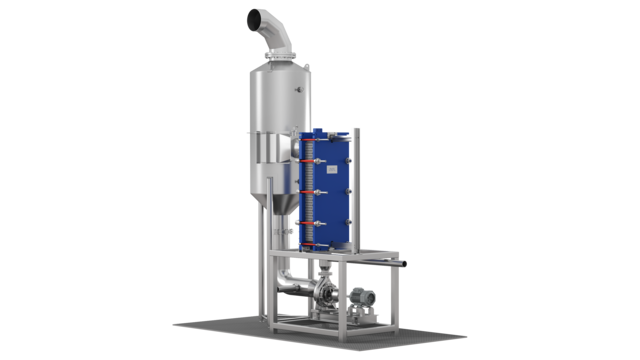

Optional jet distributor

For high-viscosity or particle-laden fluids, the jet distributor provides a robust alternative to the platter distributor. Solid cone spray nozzles, sized to match the fluid flow rate and tube sheet diameter, and larger nozzle openings reduce the risk of clogging and ensure reliable, uniform distribution in demanding shell-and-tube evaporation applications.

Gravity drives the fluid downward as a thin, continuous film along the inner tube walls. Steam applied to the outer surfaces heats the tubes, causing the liquid to boil as it flows. Vapour generated during this process accelerates the liquid film to the bottom of the tubes, where it moves into the next effect or separator stage.

This gentle, controlled process reduces surface contact time, improving thermal efficiency and minimizing fouling, especially critical for temperature-sensitive products.

Caption: The FilmVap jet distributor handles high-viscosity or particle-laden fluids.

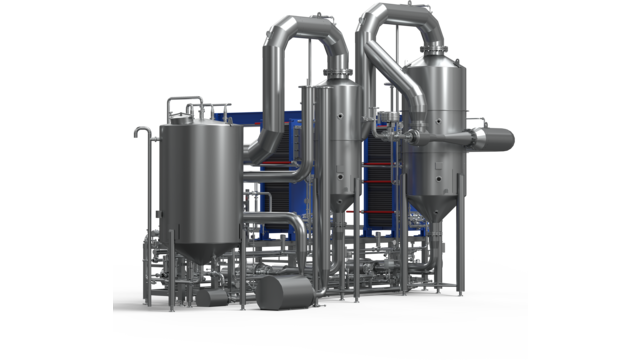

Reduce steam demand with falling film evaporators

To maximize energy efficiency, each stage of the FilmVap system operates under vacuum conditions, which lowers the boiling point and allows vapour from one effect to serve as the heating medium for the next. Vacuum pumps continuously remove non-condensable gases, while a dedicated unit condenses the final vapour to maintain the vacuum.

Using a multiple-effect evaporation setup significantly reduces steam consumption. Adding thermal vapour recompression (TVR) and/or mechanical vapour recompression (MVR) units improves energy efficiency further, cutting steam usage to a fraction of the total evaporation capacity and reducing both operating costs and environmental impact.

Happy customers

Ključni izdelki

Servis

Storitve za prehrambne sisteme

Storitve Alfa Laval za prehrambne sisteme pomagajo okrepiti učinkovitost vaših prehrambnih sistemov z zvišanjem učinkovitosti vaših procesov. Tako (se) lahko:

- Nenehno izboljšujete delovanje za ohranjanje konkurenčne prednosti

- Osredotočite na čim daljše delovanje, optimizacijo in razpoložljivost

- Povečate donosnost naložbe v celotnem življenjskem ciklu prehrambnih sistemov

Mogoče bi vas zanimalo tudi...

Explore our range of evaporators

Alfa Laval offers a wide range of evaporation systems from plate evaporators, and rising film evaporators to tubular evaporators and falling film evaporators. Find out what would work for your evaporation needs.