Aalborg OL

The Alfa Laval Aalborg OL is a large-capacity fired boiler for marine vessels that require significant amounts of steam or hot water. Available in two design pressures, 9 or 18 bar(g), it has a top-fired design that maximizes heat transfer and minimizes pressure loss. Besides operating on today’s fuels, including low-sulphur fuels and LNG, it is designed for compatibility with methanol and other future emission-reducing fuels.

Large-capacity multi-fuel fired marine boiler

- Capacity in steam and hot water production: 12,500 – 45,000 kg/h

- Capacity in dual-fuel and boil-off gas application: 10,000 – 55,000 kg/h

- Future-proof compatibility – equivalent steam capacity from future fuels compared to traditional fuels

- Easy operation thanks to straightforward and user-friendly design

- Robust and proven construction

Like all Alfa Laval Aalborg marine boilers, the Aalborg OL draws on over 100 years of experience with boilers, burners and thermal applications on board. At the same time, it comes prepared for the future. This large-capacity boiler is ready for any marine fuel in current use or under discussion, including LNG and methanol.

Developed in-house, Alfa Laval Aalborg boiler solutions are tested and optimized at the Alfa Laval Test & Training Centre and thoroughly proven at sea. Our experts ensure high thermal efficiency and the correct steam balance for your vessel, and their knowledge is always in easy reach. You have global access to boiler services that safeguard marine boiler uptime, enhance performance and lower your operating costs.

Kako deluje

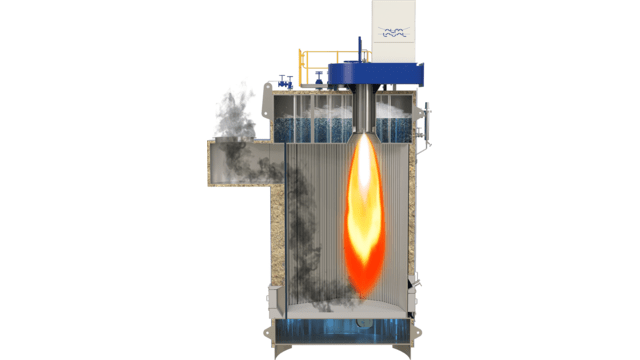

Top-fired and available in two different design pressures, the Aalborg OL is a vertical, two-drum cylindrical boiler. Straight tubes connect the water and steam drums directly, which ensures safe circulation with no risk of overheating and subsequent tube burnout.

The furnace is built with membrane walls, which are constructed from gastight polygonal panels that make it resistant to gas pulsations. Containing only a minimum of refractory material, it is shaped to provide optimal combustion conditions. The convection section consists of straight pin tubes with bent pins, which provide a high coefficient of heat transfer and ensure low pressure loss. Circulation is promoted by downcomers placed outside the membrane walls.

Design data

Dual-fuel and boil-off gas application

- Design pressure: 9 or 18 bar(g)

- Capacity: 10,000–55,000 kg/h

Ship types

- VLCC tanker

- Suezmax tanker

- Aframax tanker

- Panamax tanker

- FPS unit

Steam and hot water production

- Design pressure: 9 or 18 bar(g)

- Capacity: 12,500–45,000 kg/h

- Burner recommendation: Alfa Laval Aalborg KBSD pressure-atomizing burner

Aalborg marine boiler solutions for LNG as fuel

Alfa Laval Aalborg dual-fuel boilers are more than an efficient solution for your steam and hot water needs. Able to handle both free flow and methane mixed with inert gas, they provide safe, effective ways to manage boil-off gas (BOG) and simplify operations connected with tank inspection.

Aalborg marine boiler solutions for Methanol as fuel

Built on a century of thermal expertise, Alfa Laval Aalborg boilers are prepared to run on methanol, thanks to our future-proof MultiFlame burner concept. Adding to our already extensive combustion knowledge, we are now conducting large-scale methanol testing at the Alfa Laval Test & Training Centre.

Alfa Laval Test & Training Centre

Reliability is paramount in equipment for LNG use. Alfa Laval achieves it not only through years of experience but also through extensive testing at the Alfa Laval Test & Training Centre. This unique facility has an entire section dedicated to ensuring safe, efficient gas operations.